Jianli Zeng

Research Institute of Petroleum Processing, SINOPEC, China

Biography

Dr. Jianli Zeng is a senior engineer of the long-term project research department in Research Institute of Petroleum Processing, Sinopec. He mainly focuses on biodiesel preparation and its applications in fuel or fine chemical fields. Dr. Zeng spent over 10 years on biodiesel research and his latest achievement was the invention of SRCA-II process which had been verified in a 2000 t/a pilot plant.

Abstract

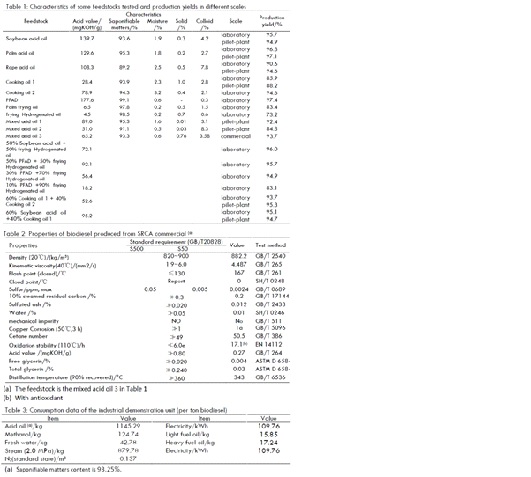

Statement of the Problem: Biodiesel generated from oil is an attractive biofuel, while the high production cost hinders its development. As the cost of raw materials accounts for about 70% of the total production cost, using low-grade but cheap feedstock is an effective way to reduce cost. Low-grade oils usually contain high content of free fatty acids (FFA), water and unsaponifiable matters. These impurities make it impossible to converted low-grade oils to biodiesel via homogeneous alkali or heterogeneous catalyst catalyzed process. Supercritical methanolysis (SCM) technology which doesn’t require the presence of catalyst has shown its adaption to low-grade feedstocks and friendliness to environment. Though SCM technology exhibits good feedstock flexibility, fast reaction rate and high product yield, the harsh reaction conditions ( ~ 350 ℃ , ~ 20MPa) preclude its commercialization. The purpose of this study is to introduce a mild catalyst-free biodiesel process which is also suitable for low-grade feedstocks and easy to industrialize. Methodology & Theoretical Orientation: The mild catalyst-free biodiesel process (named SRCA process) has been explored on laboratory continues devices and tested in a 2000t/a pilot-plant. Engineering and scale-up problems have been studied and verified in the pilot-plant and a 60000t/a industrial unit. Various oils, including crude plant oils, acid oils, waste cooking oils, PFAD etc. have been used to examine the feedstock flexibility. Findings: FFAs and glycerides in low-grade oils can simultaneously react with methanol in SRCA process under mild conditions (<280℃, <10MPa) . With appropriate heat transfer technology and product separation technology, most tested oils can be converted to biodiesels with high yield. The standard coal consumption of the commercial unit is 145.36 kg/t biodiesel. Conclusion & Significance: The mild catalyst-free process has been proved from laboratory to commercial scale, so it’s worthy to be applied in more factories.