Streffer F

LXP Group GmbH, Germany

Biography

Katrin Streffer is the Co-Founder of LXP. Prior to founding LXP (formerly maxbiogas) in 2009, she was the Head of R&D of a medtech company, financed by venture capital. At the beginning of her career, Katrin worked as a Research Associate at the Charité – University Medicine Berlin on her own project. Her work was mainly focused on the development of new laboratory tests. In 2007 she joined the start-up medtech company, Gilupi GmbH. In her position as a Chief Scientific Officer she was responsible for the management of R&D projects and product development, e.g. the development of the CellCollector® the first CE approved in vivo CTC isolation product worldwide. She holds a degree in chemistry from the Technical University of Berlin, Germany, and a PhD in Analytical Biochemistry from the University of Potsdam, Germany. She is author and co-author of multiple scientific publications

Abstract

Today primarily 1st generation (1G) biomass is used to produce bio-fuels and bio-based chemicals, i.e. starch and sugar extracted from renewable feedstocks such as corn and sugar cane. At the same time, literally billions of tons of 2nd generation (2G) biomass are available but vastly underutilized, i.e. agricultural straws and other residues. The LX-Process is a proprietary technology that “gently” crack the structural bonds of 2G biomass, making available the main components cellulose, hemicellulose (both complex sugars) and natural lignin. Sulfur free lignin can be extracted and the sugars processed to bio-fuels and bio-based chemicals. In other words: the process converts mostly worthless agricultural residues to high value-added bio-fuels and bio-based chemicals. In addition to the enormous increase in feedstock flexibility, the technology allows a substantial increase in yield from conventional (1G) feedstocks.

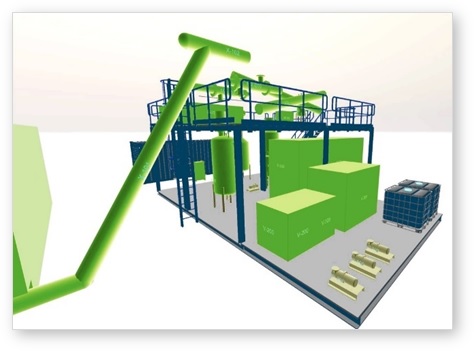

Figure 1 shows a 3D picture of the LX-Demo Plant. Main advantages of LX-Plants are:

- Using raw materials which are hitherto residues or waste products. In bio-refineries, these are, e.g. plant residues, which commercial use is only possible after pretreatment.

- Easy integration of pretreatment, conversion and downstream processes with as low purification efforts in between as possible.

- Easy integration with bioprocesses without detoxification (demonstrated by the biogas process), so cellulolytic bacteria like different Clostridia grow happily on our carbohydrates.

- Commercial enzyme preparations easily degrade our carbohydrates to monomeric sugars, since the carbohydrates are regenerated from solution and are mostly amorphous.

- The LX-Process is a low temperature pretreatment process below 80°C, which prevents the formation of inhibitors like furfurals or short chain phenols and allows the utilization of waste heat

- A high carbohydrate yield of usually over 90% is obtained, since side reaction to inhibitors do not play a significant role